The Hidden Beast in a Handrail Project

Ah, the sweet smell of overconfidence—right before reality smacks you in the face with unexpected angles and slopes. You know that feeling when you take on a project thinking it’ll be smooth sailing, only to realize halfway through that you’ve actually stepped into a metalworking horror movie? Yeah, me too. Welcome to my latest adventure: the handrail project from Provo.

I don’t know the full backstory, but my client built an amazing ramp for an elderly couple in his neighborhood. This thing was a masterpiece—25 feet long, twisting and turning down from the front porch, over a cement path, and all the way to the sidewalk. But here’s the kicker: at every bend in the ramp, the slope and the angle changed. I mean, seriously? Who designed this, a rollercoaster engineer?

Turning Chicken Scratches into Metal Art

Back at the shop, I stared at my notebook full of chicken-scratch sketches, trying to make sense of what I had gotten myself into. The only way to ensure the handrails fit perfectly was to recreate the ramp in my shop. So, off to Home Depot I went, bidding farewell to my budget as I stocked up on lumber and screws. Yep, an unplanned expense—but hey, at least I got to play with wood for a change.

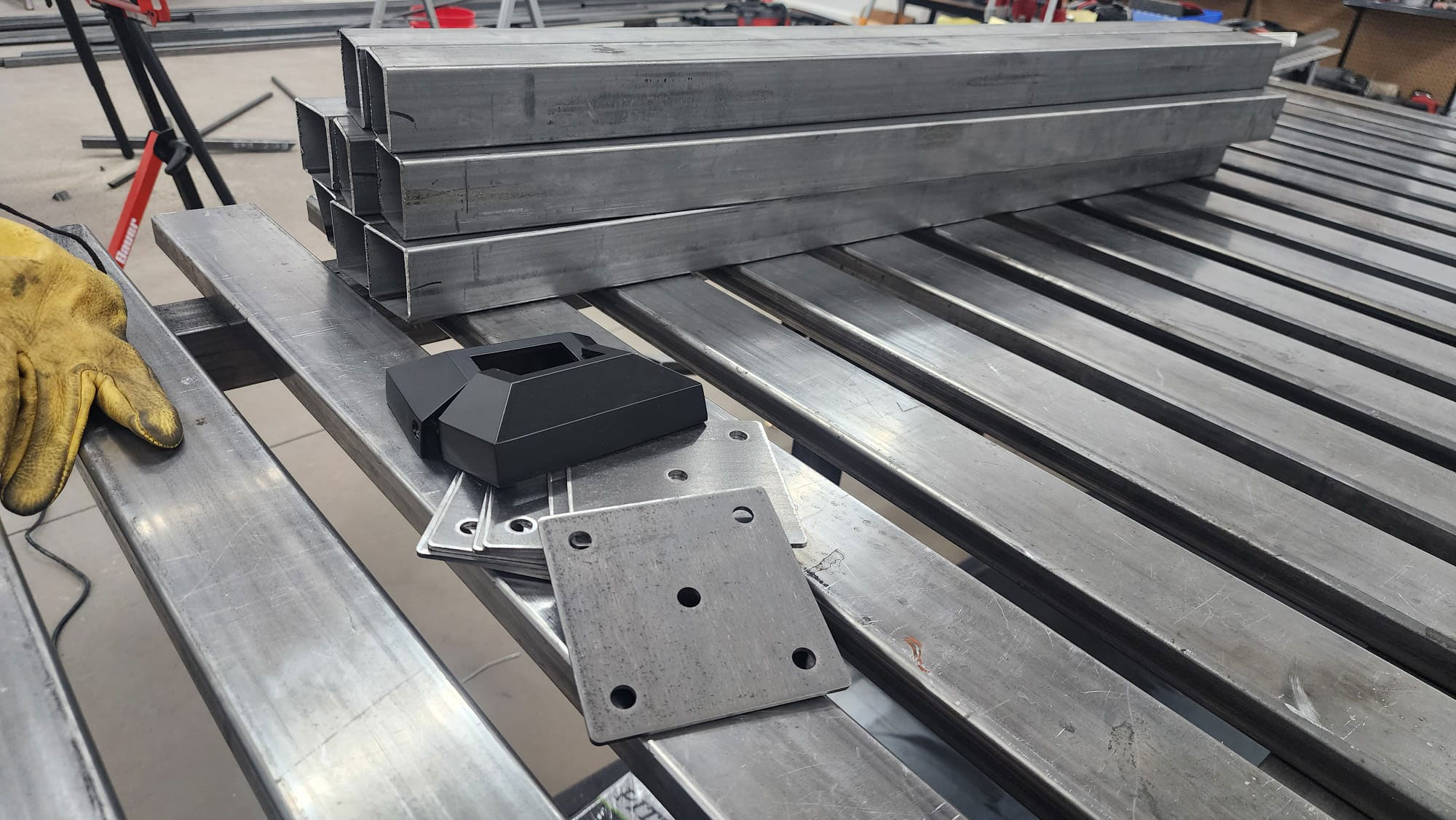

The railings themselves were made of 2″ square posts, with 2″x1″ top and bottom rails, and 1/2″ balusters spaced evenly at 4″ apart. Simple, right? WRONG. The number of hours I spent on AutoCAD trying to work through the ever-changing slopes and angles would make your head spin. If you ever want to question your life choices, try designing a handrail for a ramp that has more angles than a geometry final.

The Transportation Dilemma

Then came the next challenge—how do I transport this monster being a one-man shop? While I do have a pretty sweet gantry crane, using it for this wasn’t the best solution. (Yes, I know you’re thinking, “Dude, use the crane!” No thank you. Now go sit in the corner and think about what you’ve done.)

Instead, I activated my secret superhuman powers (patent pending) and designed a modular sleeve system that allowed me to break the railings into sections for easy transport between my shop, the client’s house, and the powder coating shop. And guess what? It worked beautifully! Just another day of turning chaos into slightly less chaos.

Perfectionist’s Curse & Midnight Panic

When I test-fitted the railings back at the client’s house, they looked good—but not good enough for me. You see, I suffer from a rare condition known as Fabrication OCD—a relentless urge to make things so perfect that even my tape measure starts rolling its eyes at me. The angle on the balusters was off by about 1.5 degrees, and that just wasn’t going to fly.

Back at my secret welding lair, I stared at the section of railing that contained nearly 80 welds. Cutting and realigning it? Yeah, not happening unless I suddenly gained the patience of a saint (spoiler: I haven’t). Then, as I scanned my shop, I spotted my trusty come-along. Cue the Aha! moment.

I secured the bottom-most corner of the section to one of my shop’s steel frames, then grabbed a 10,000 lb strap and hooked up my come-along to another steel frame. With all the strength of a man determined to win a battle against metal itself, I heaved, hoisted, and pulled—checking my progress with my trusty digital angle finder. And you know what? IT WAS WORKING. It felt like I had unlocked the ability to manipulate the very fabric of time—well, almost. I was just bending metal, but close enough.

Feeling victorious, I thought, Hey, I’ll just leave this torqued tight overnight, and by morning, everything will be perfect. Genius, right?

Jigging Up for Success

Fast forward to 11:00 PM—I’m tossing and turning in bed, picturing my entire shop collapsing because of my brilliant idea. My wife, already used to my middle-of-the-night metalworking crises, asked what was wrong. I explained my completely rational fear that I had just engineered my own shop’s destruction.

Without missing a beat, she convinced me to drive back to the shop at midnight to release the tension. So there I was, in the middle of the night, undoing my master plan while questioning my life choices. Gotta love that woman and her patience with me.

Lessons Learned

Measure twice, cut once. Seriously, this old saying is no joke. With so many angles and variables, taking the time to measure meticulously, draw it up in AutoCAD, and study every detail made all the difference. If you don’t, well… let’s just say grinding welds is a humbling experience.

Work with great clients. I lucked out with this one—Ryan was patient, understanding, and easy to work with. That makes a HUGE difference. If you ever find a client who doesn’t mind when you temporarily turn their yard into a metal shop, cherish them.

Perfection is overrated. When dealing with a project that has a million moving parts (literally), you have to accept that nothing will be 100% perfect. Trust your skills, do your due diligence, and when in doubt, call your support team for a round of free affirmations.

Final Thoughts (or, “Would I Do This Again?”)

At the end of the day, the project turned out freaking amazing. The welds? Oh, they were sexy—like stacked dimes fresh out of a welding fantasy. The craftsmanship? Top-notch. The final install? Flawless.

Would I do it again? Absolutely. Would I obsess over the angles again? 100%. Because at the end of the day, there’s nothing more satisfying than seeing a perfect railing in place and knowing I made that happen.

Stay tuned for final pictures—because this beauty deserves to be shown off.

And hey, if you ever need a custom handrail that looks like a work of art, you know who to call. Just don’t expect a straight answer when you ask, “How hard can it be?”

BONUS: If you actually read this entire thing and call me out on it, lunch is on me after I complete your project. (No, seriously. I’ll even let you pick the place—within reason. No five-star steakhouses. I weld, I don’t print money.)